The whole machine adopts imported servo motor, imported high-speed spindle, and the drive screw uses precision ball screw; it can perform single drilling, single tufting, and the unique rotary conversion clutch is used for the drilling tufting head selection method, and the drilling and tufting regular hole position editing, The computer can automatically assign and calculate the program, reducing the cumbersome steps of using the handwheel to teach the input of the holes one by one.

CP-2.3-108ML250HDSPRODUCT CENTER

Large airport/road snow removal brush with two drills and one planting machine

| category | Configuration parameter |

| Number of axes | Two axis |

| X axis travel |

2000mm

|

| Z axis rotation angle |

360°

|

| X, Y axis guide | Using original imported linear guide |

| X-Y axis repeat positioning accuracy |

±0.01mm/100mm

|

| Processing stick brush length |

300mm-1200mm

|

| Diameter of processing roller brush |

∮50-280mm

|

| Pore distribution | In-line, plum blossom, herringbone, spiral |

| Drilling hole diameter range |

1.0-10mm

|

| Flocking aperture range |

3.0-8.0mm

|

| Drilling and planting speed | Up to 3-5 holes/sec (depending on the hole distance and angle requirements) |

| Hair transplanting method | Horse tack |

| The total length of the tufted hair before being folded in half |

50mm-145mm

|

Large-scale airport/road snow removal brush with two drills and one planting machine, X and Z two-axis operation, suitable for drilling and planting of large barrel brushes. The processing length of the longest round barrel brush is within 1280mm, and the maximum outer longitude can reach 680mm after the brush handle is transplanted.

The whole machine adopts imported servo motors, high-speed electric spindles, imported precision ball screws and LM guides. The parts used in the assembly of the whole machine are processed by imported machining centers (CNC) and grinders, with high precision. , So after-sales maintenance is convenient. Through computer editing, single drilling, single planting, and drilling and planting can be performed in a left and right cycle; the shape of the stick brush hole position, such as straight, plum blossom, spiral, herringbone, etc., can be automatically assigned and calculated by the computer, which is convenient and fast; adopts a new design The hair transplanting machine head is more stable and faster; the sliding part of the machine head bearing is equipped with an electric oil pump, which continuously circulates oil supply and recovery, which prolongs the service life of the parts. The fixture can withstand a roller brush weighing up to 180kg.

This equipment can make single-color or two-color brushes according to the needs of customers, and it can also process disc brushes by changing the fixture.

| category | Configuration parameter | category | Configuration parameter |

| X axis travel |

3100MM

|

Manual up and down adjustment stroke of the machine head |

0-130MM

|

| Brush handle outer diameter |

¢180-¢300

|

Hair transplant aperture |

¢4-¢10

|

| Maximum outer diameter of brush handle after transplanting |

¢680

|

Planting speed | 2 holes/sec |

| Maximum tuft length | 200MM (see light hair length) | Hair box | monochrome |

| Maximum length of brush handle |

1280MM

|

Hair transplanting method | Martin |

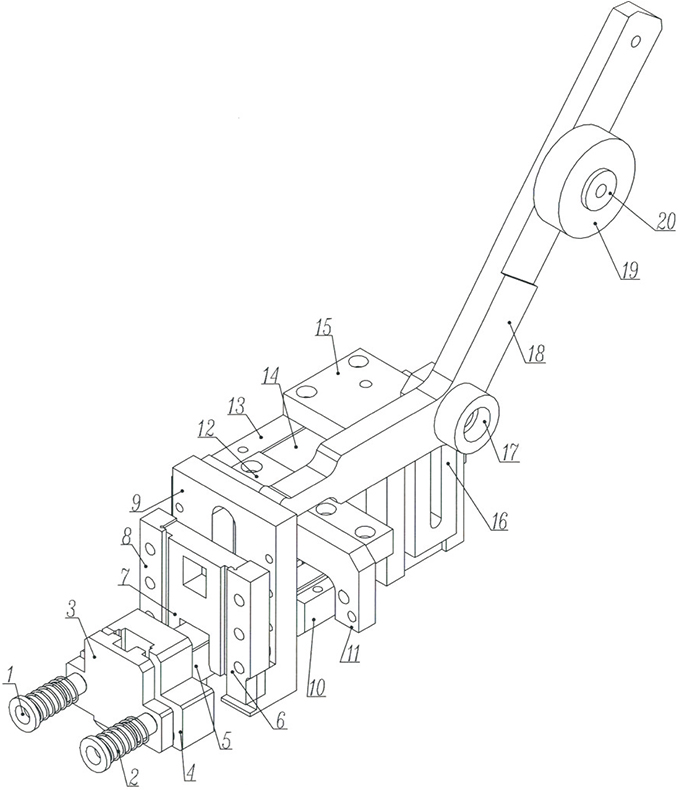

Assembly drawing of the core part

All parts produced by our company are numbered and named uniformly, and there is a complete set of drawings (a set is also allocated to the customer when the machine is shipped, and the assembly drawing of the cutter core part is shown in the figure below), based on high standards and high precision. It is ensured that the same parts produced in different periods can be interchanged.

All parts produced by our company are numbered and named uniformly, and there is a complete set of drawings (a set is also allocated to the customer when the machine is shipped, and the assembly drawing of the cutter core part is shown in the figure below), based on high standards and high precision. It is ensured that the same parts produced in different periods can be interchanged.

| Serial number | Drawing number | name | quantity |

|

1

|

CP-108MTL250H-N2

|

Knife core spring sleeve |

2

|

|

2

|

|

Knife core spring sleeve spring-T |

2

|

|

3

|

CP-108MTL250H-

|

Pressure needle 10-36 |

1

|

|

4

|

CP-108MTL250H-

|

Upper and lower mold 10-35-1.8 |

1

|

|

5

|

CP-108MTL250H-

|

Push line block 10-35-1.8 |

1

|

|

6

|

CP-108MTL250H-

|

Right guide plate 35 gantry |

1

|

|

7

|

CP-108MTL250H-

|

Tangent body 10-1.8-35 |

1

|

|

8

|

CP-108MTL250H-

|

Left guide plate 35 gantry |

1

|

|

9

|

CP-108MTL250H-

|

Knife core support plate 9.0-36-1.2 |

1

|

|

10

|

CP-108MTL250H-

|

Press block 10-1.8-35 |

1

|

|

11

|

CP-108MTL250H-

|

Knife flower support plate |

1

|

|

12

|

CP-108MTL250H-

|

Clamping block locking seat 10-1.8-35 |

1

|

|

13

|

CP-108MTL250H-

|

Knife core base |

1

|

|

14

|

CP-108MTL250H-

|

Line pusher |

1

|

|

15

|

CP-108MTL350H-

|

Knife core cover |

1

|

|

16

|

CP-108MTL250H-

|

Tangent crossbar support |

1

|

|

17

|

CP-108MTL350H-

|

Crossbar compression sleeve |

1

|

|

18

|

CP-108MTL250H-

|

Tangent bar |

1

|

|

19

|

6301

|

Bearing |

1

|

|

20

|

CP-108MTL350H-

|

Tangent wheel spindle |

1

|

About Us

The company is a wholly-owned company established by Hong Kong Zhifeng mechanical CNC System Co., Ltd. in Anlu, Hubei Province in March 2005. It is a company specializing in the design and manufacture of various professional CNC machinery with mechatronics technology. It has won the "excellence award of the first governor's industry award" in Hong Kong in 1989 and the "excellence award of machinery and design" of Hong Kong manufacturers association in 1995. Now it is mainly engaged in the manufacturing of number control brush machinery, with a long history.

SAUNDERS

WRITE A MESSAGE TO US